- The Weekly Nugget

- Posts

- Fixing a Linear System

Fixing a Linear System

The startup on a mission to expand the circular economy.

Whether you’re manufacturing phones, computers, and televisions in Asia or robots and other advanced devices in the United States, the common thread is that there is a lot of electronic waste headed for disposal.

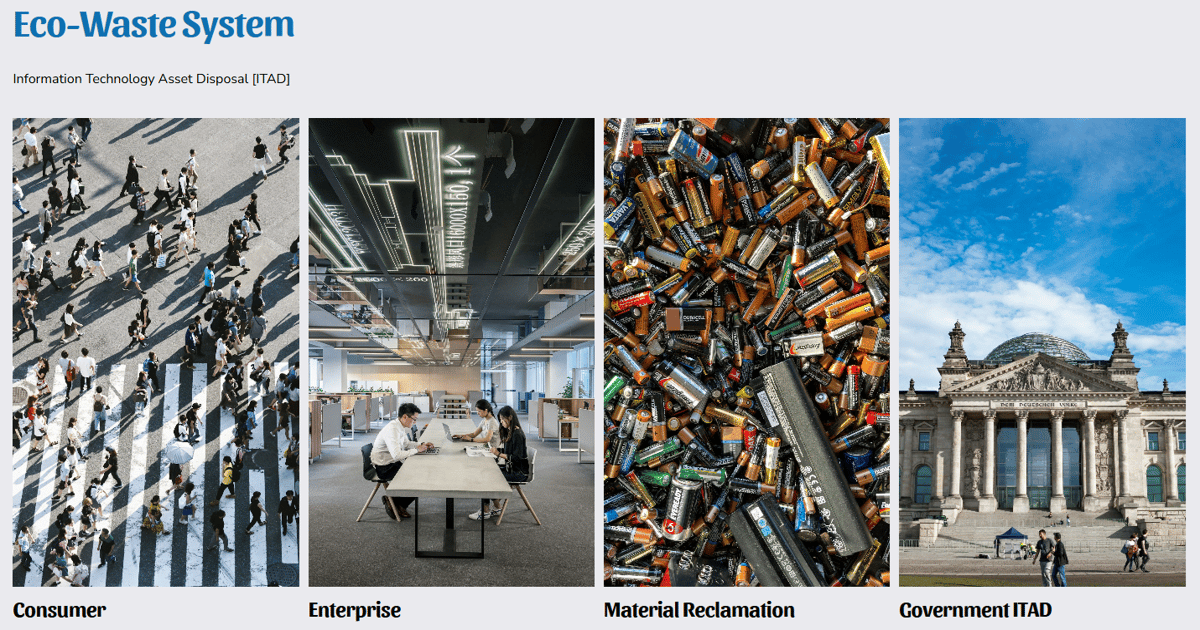

Each year, 400 million electronic devices or 62 billion kilograms of electronic waste gets discarded - of which only 22% is recycled. Whether its from the factory, warehouses, a large facility, government agencies, or at the household consumer level - only 22% of this e-waste is being re-used, refurbished, recycled, or re-integrated back into the economy.

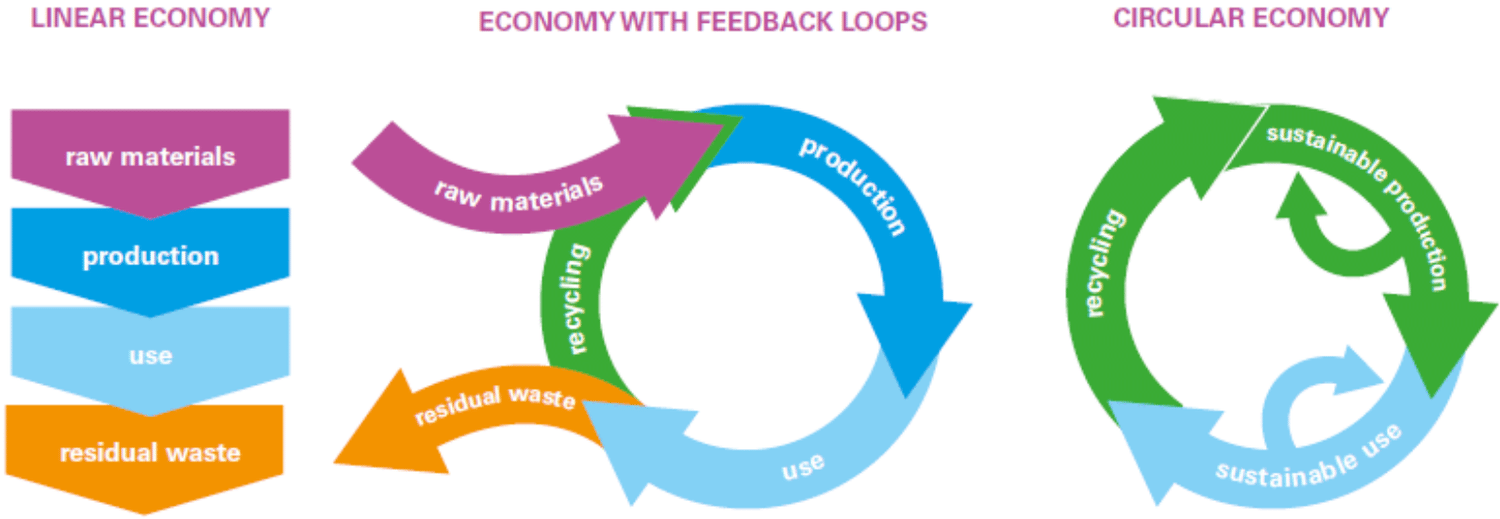

The 80% that’s headed to the landfill is typically due to this “single use” linear economy where traditionally products have been designed, manufactured, and disposed of at perceived end of life. Much of the time these are small devices, electronics, and appliances, but account for a large percentage of toxic contamination at landfills.

In decades past, this may not have been as big of a problem, as American products were made to last 20, sometimes 30 years. However, since the early 2000s, products have been engineered to serve a shorter single use product lifespan (across most industries).

Much of the reasoning being to require fewer raw material inputs, and increase industry lifecycle turnover - thus making industries much larger in potential revenue. A simple example is that if your product goes from lasting 20 years to lasting 5 years, you’ve just quadrupled the size of that market because you’re going to see 4 times the sales over a 20 years period. Thus, we created an even bigger need for a circular economy.

Many brands are thinking about sustainability during the initial product design phase today, and a second life for their products and electronic components inside them. However, it’s largely still industry talk and marginal gains in terms of the big picture progress - leaving a circular economy gap of 80%.

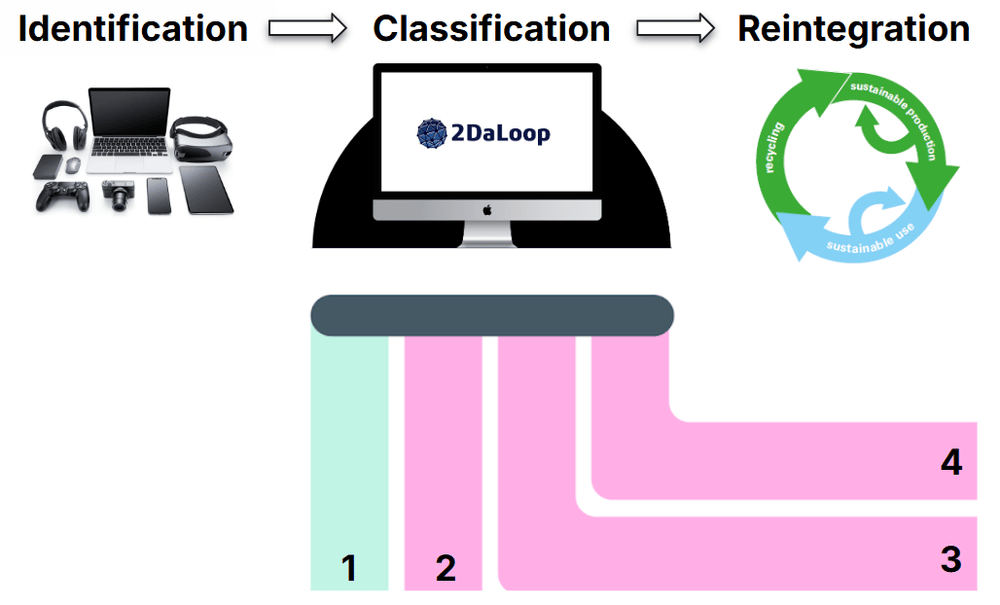

The Solution: Identify, Classify, and Reintegrate.

The solution to solve this problem from a manufacturing standpoint can look similar to what companies like Apple have done - creating a robot that does a quick breakdown of their phones into reusable components in just minutes.

However, to address the entire industry there needs to be a solution that can identify e-waste, classify it into an acquirable category, and then logistically re-integrate it into the economy. An industry wide solution such as this could make a huge impact on this 80% circular economy or “landfill gap”.

An app that empowers manufacturers, large facilities, and consumers to offload their end of life e-waste into the circular economy virtually with a material reclamation facility or second life refurbishment partner has high potential to solve this big problem.

This is what makes the startup 2DaLoop unique.

At 2DaLoop, they’ve been deep in research and development on how to make this vision a reality. Think of 2DaLoop as the Google Maps of the e-waste world. Just as you use Google Maps to see the possible routes to get from point A to point B, 2DaLoop creates opportunity pathways for valuable electronic waste to be recycled and reintegrated into the supply chain.

The 2DaLoop team is working towards launching an industry app that will potentially provide manufacturers, consumers, and large facilities with a marketplace to offload their e-waste for financial gain, while recyclers and re-furbishers can easily acquire e-waste to scale their businesses. Thus, creating new markets for e-waste while also addressing the 80% “landfill gap”.

The 2DaLoop Team, and Traction.

This has been a momentous year for 2DaLoop’s seasoned tech leadership team having been invited to be part of Gener8tor (North Dakota gBETA), the Clean Tech Open, gBETA Autonomous Systems, Nextcycle Michigan, and the Centropolis Accelerator.

Currently, they are connecting with industry partners to join the September 2nd app beta launch to work towards a scalable version of the software in 2026. If you are a recycler or manufacturer, you can learn more on the 2Daloop website here.